The spraying production line for glass wine bottles generally consists of a spray booth, a hanging chain and an oven. Glass bottles and the front water treatment, glass bottles need special attention to the problem of sewage discharge. As for the quality of glass bottle spraying, it is related to water treatment, surface cleaning of the workpiece, electrical conductivity of the hook, the size of the air volume, the amount of powder spraying, and the level of the operator.

It is recommended to choose the following methods to try:

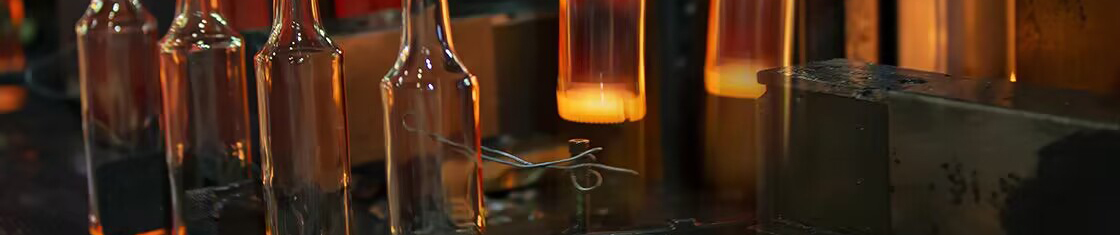

1. Pre-processing section. The pre-treatment section of glass material wine bottle spraying includes pre-stripping, main stripping, surface adjustment, etc. If it is in the north, the temperature of the main stripping part should not be too low, and it needs to be kept warm. Otherwise, the processing effect is not ideal;

2. Preheating section. After the pretreatment, it will enter the preheating section, which generally takes 8 to 10 minutes. When the glass bottle reaches the powder spraying room, the sprayed workpiece should have a certain amount of residual heat to increase the adhesion of the powder;

3. Glass wine bottle soot blowing purification section. If the process requirement ratio of the workpiece to be sprayed is relatively high, this section is essential, otherwise, if there is a lot of dust adsorbed on the workpiece, the surface of the workpiece after processing will have a lot of particles, which will reduce the quality;

4. Powder spraying section. Glass bottle is a traditional beverage packaging container in my country, and glass is also a very historical packaging material. With many kinds of packaging materials flooding into the market, glass containers still occupy an important position in beverage packaging, which is inseparable from its packaging characteristics that cannot be replaced by other packaging materials. The key to this section is the technical problem of the powder spraying master. If you want to create good quality, it is still very worthwhile to spend money on a skilled master.

5. Drying section. What should be paid attention to in this section is the temperature and baking time (explain: bake things with fire-dried objects), and the powder is generally 180-200 degrees, depending on the material of the workpiece. Also, the drying furnace should not be too far away from the powder spraying room, generally 6 meters.

Long-term consumption of food contaminated with polyethylene molecules will cause dizziness, headache, nausea, loss of appetite, memory loss, etc., and even anemia. Therefore, the use of plastic bottles for seasoning is harmful to human health without any benefit.

In the family, glass bottles can be used instead of plastic bottles to hold condiments and so on. Pay special attention when using plastic bottles, do not touch vinegar, detergents, etc., avoid direct sunlight, high temperature, etc., to avoid chemical reactions.

In addition, when you buy plastic tableware, you should choose plastic products with PE (polyethylene) or PP (polypropylene) labels, few decorative patterns, colorless and odorless, and smooth surface.

Post time: Apr-20-2022